Our staff will be more than happy to examine all requests from manufacturers, industries, municipalities or specialized contractors, and propose a customized solution.

Contact Us

Founded in 2008 to meet a specific need in the field of water treatment, TEKK gradually extended its activities to the environmental and industrial sectors. In complementarity with our clients and partners, our team have been involved in more than 1000 project of all scopes.

While offering a healthy working environment to our team and partners, TEKK’s mission is to present products of irreproachable quality, meeting the needs of each project, at competitive prices.

Our quality system meets the requirements of ISO 9001:2015 and each product is CSA and cULus certified.

Needs differ from one contract to another. Therefore, we recommend an adaptive approach for each client or contract. We will find a way to meet your requirements, whatever expectations may be.

![]()

Consult the technical sheets:

![]()

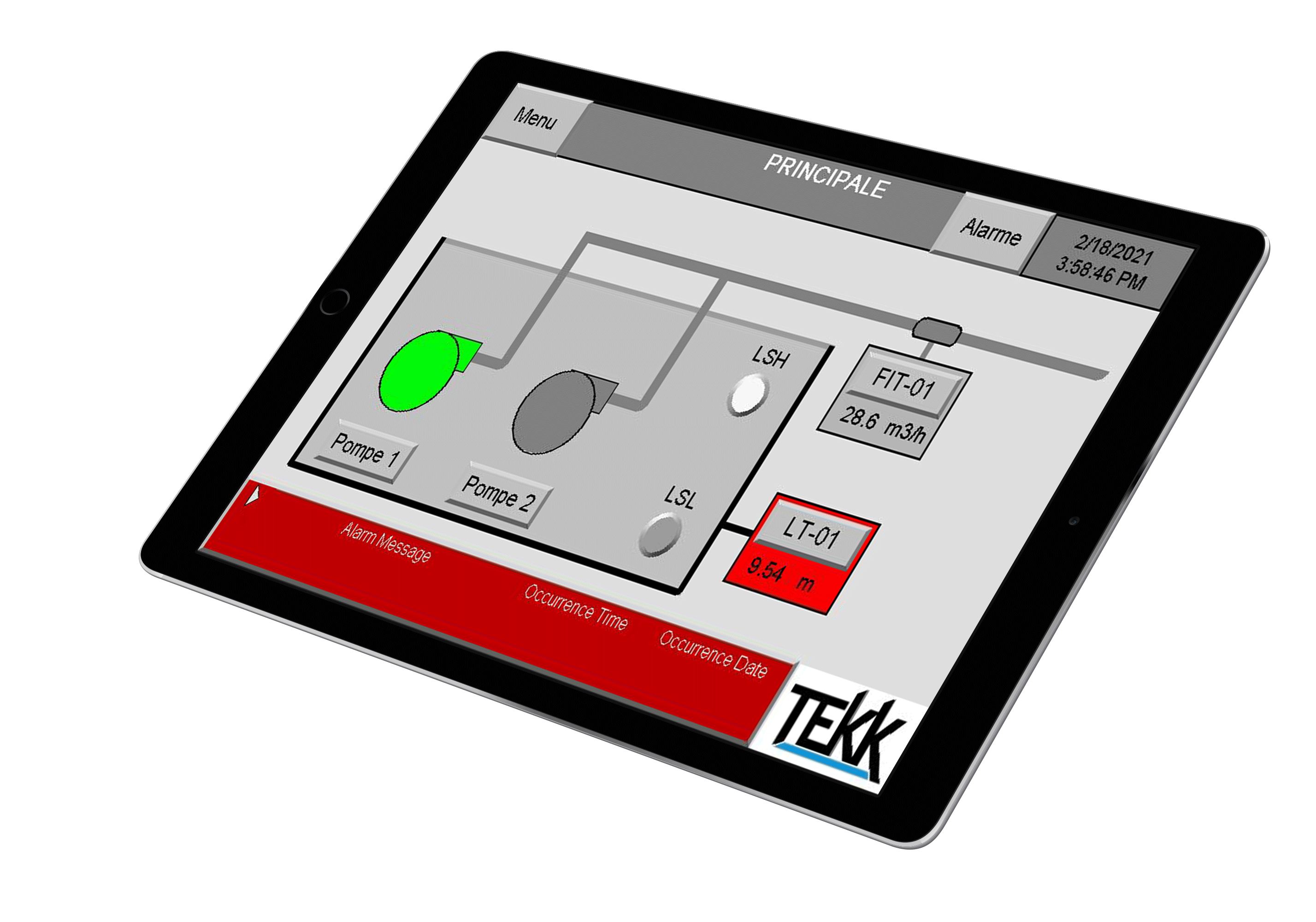

Our automation department is able to offer integrated solutions for the control and monitoring of your processes.

![]()

Whether it is for analysis, maintenance, optimization or emergency troubleshooting of your systems, we will be happy to help you solve your problems.

Manufacture of control panels for the biogas cogeneration plant including: main - secondary control panels, junction boxes

Manufacture of control panels for the biogas cogeneration plant including: main - secondary control panels, junction boxes

Manufacture of control panels for the biogas cogeneration plant including: main - secondary control panels, junction boxes

Manufacture of control panels for the complete upgrade of Auteuil wastewater treatment plant including: control panels, motors starter panels and networking cabinets

Design and manufacture of control panels for the upgrade of the Atwater water treatment plant - Sodium hypochlorite generation system including: control panels, alarms panels

Design and manufacture of control panels for a new water treatment plant (Membrane water treatment) including: control panels, networking cabinets

Design and manufacture of control panels for a new water treatment plant (Membrane water treatment) including: control panels, networking cabinets

TEKK Controls

430, rue des Entrepreneurs

Québec (Québec) G1M 1B3

T 418 683-8773

info@tekkcontrols.com

Jonathan Robitaille – Director

jonathan.robitaille@tekkcontrols.com

David Martin – Technical support

david.martin@tekkcontrols.com

© 2024 Les Panneaux de Contrôle TEKK | A realization of Andréanne Patry and Francis Santerre